Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

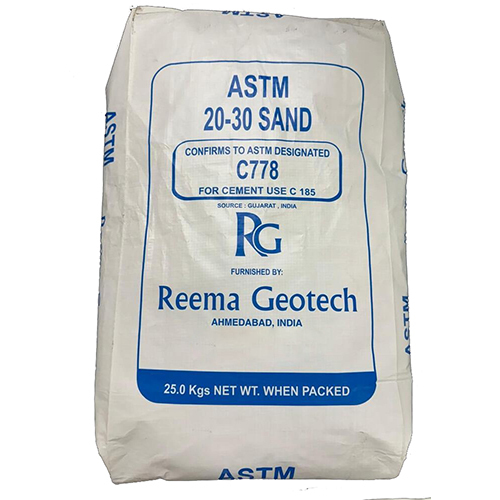

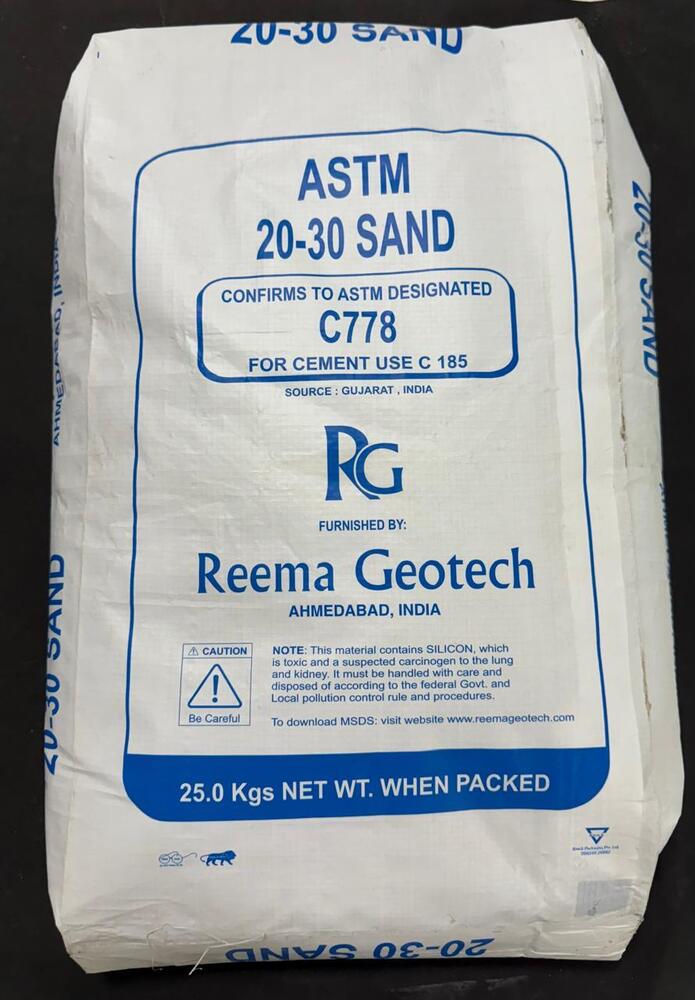

Mon - Sat : 9.00 AM - 6.00 PMASTM C778 20/30 SAND

Product Details:

- Bending Strength Subject to mortar mix design

- Fineness Passed through ASTM standard sieves No. 20 and No. 30

- Initial Setting Time Not applicable to sand

- Application Cement Mortar Cube Testing, Quality Control Laboratories, Cement Testing, Research and Development

- Weight 50 kg bags (typical), Bulk options available

- Compressive Strength Conforms to ASTM C109 specification when used as per ASTM C778

- MgO % Less than 0.5 %

- Click to View more

ASTM C778 20/30 SAND Price And Quantity

- INR

- 3 Ton

ASTM C778 20/30 SAND Product Specifications

- Standard ASTM C778 Grade

- 50 kg bags (typical), Bulk options available

- Used to ensure standard setting in cement testing

- Cement Mortar Cube Testing, Quality Control Laboratories, Cement Testing, Research and Development

- Not applicable to sand

- High Purity, Consistent Grading, Dried and Screened

- Less than 0.5 %

- Natural light beige to white

- Portland Cement Testing

- Less than 0.5 %

- Conforms to ASTM C109 specification when used as per ASTM C778

- Standard Sand for Cement Testing

- Subject to mortar mix design

- Natural Silica Sand

- 20/30 (mesh)

- Quartz Silica Sand

- Passed through ASTM standard sieves No. 20 and No. 30

ASTM C778 20/30 SAND Trade Information

- 50 Ton Per Day

- 7 Days

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

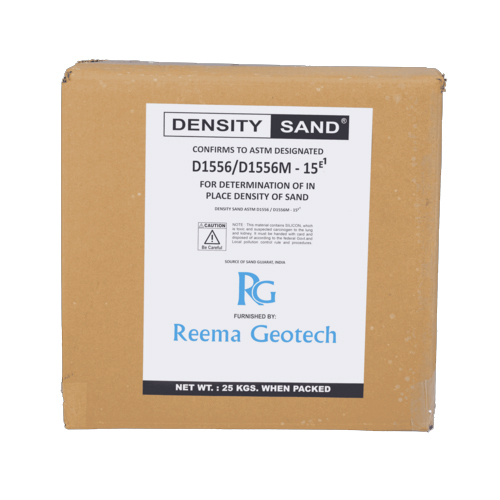

ASTM C778 specifies standard sand for use in the testing of hydraulic cements. The "20/30 sand" is one specific type of sand covered by this standard, often referred to as "tensile test sand."

Here's a description of ASTM C778 20/30 sand:

Key Characteristics:

* Composition: It is typically a natural silica sand, meaning it's primarily composed of silicon dioxide (SiO2), often with a silica content of 98% or higher.

* Grain Shape: The constituent grains are usually uncrushed and have a rounded or sub-rounded form. This is important for consistent packing and flow properties in testing.

* Water Content: It typically has a very low water content, usually less than 0.1%.

* Standardization: It must meet strict requirements for grading and be free from undesirable air-entraining characteristics.

Sieve Analysis (Grading) Requirements for 20/30 Sand (ASTM C778):

The "20/30" designation refers to its particle size distribution, specifically that it primarily passes through a No. 20 sieve and is retained on a No. 30 sieve. The exact percentages passing various sieves are critical for its standardization:

* 1.18 mm (No. 16) sieve: 100% passing

* 850 µm (No. 20) sieve: 85% to 100% passing

* 600 µm (No. 30) sieve: 0% to 5% passing

Purpose and Use:

ASTM C778 20/30 sand is considered a "standard sand" because its consistent and controlled properties make it ideal for:

* Testing Hydraulic Cements: It's primarily used as a reference material in various standard tests for hydraulic cements, such as:

* ASTM C185: Standard Test Method for Air Content of Hydraulic Cement Mortar.

* ASTM C190: (Discontinued standard, but 20/30 sand was used for tensile strength of hydraulic cement mortars).

* ASTM C109: Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (while "graded sand" is more common for this, 20/30 sand may also be referenced or used in specific contexts).

* Ensuring Reproducibility: By using a standardized sand, laboratories can minimize variations in test results due to aggregate properties, thus ensuring the comparability and reproducibility of cement tests.

In essence, ASTM C778 20/30 sand is a precisely controlled, rounded silica sand designed to provide a consistent and reliable aggregate for critical tests of hydraulic cements.

Precision and Reliability in Cement Testing

ASTM C778 20/30 Sand is renowned among laboratories and manufacturers for its consistent grading and high silica purity, ensuring reproducibility in cement testing. Its rounded to sub-angular particle shape and low impurities maximize the reliability of mortar cube strength measurements, essential for standard compliance and effective material analysis.

Superior Material Handling and Packaging Options

Delivered in robust 50 kg polypropylene bags with the option for custom packaging, this standard sand offers ease of handling and bulk availability for diverse industrial and laboratory requirements. Its indefinite shelf life, when stored dry, guarantees long-term usability and stability for ongoing research and quality control operations.

FAQ's of ASTM C778 20/30 SAND:

Q: How is ASTM C778 20/30 Sand used in cement testing applications?

A: ASTM C778 20/30 Sand is employed primarily in cement mortar cube testing to assess the compressive and bending strength of Portland cement. Its standardized grading and purity provide a controlled environment for comparative laboratory analysis, ensuring test consistency as per ASTM C778 and related specifications.Q: What benefits does using ASTM C778 standard sand offer for quality control laboratories?

A: Utilizing ASTM C778 standard sand in quality control processes enables highly reproducible results, thanks to its consistent particle size, low impurity levels, and high silica content. This facilitates accurate benchmarking of cement batches and ensures conformance with international testing standards.Q: When should this sand be used for cement research or testing?

A: ASTM C778 20/30 Sand should be used whenever laboratory testing demands standardized sand for precise evaluation of cement characteristics, especially for compressive and bending strength analysis. It is suitable for both routine quality control and research and development applications.Q: Where can ASTM C778 20/30 Sand be sourced and is bulk ordering available?

A: This sand is manufactured and supplied in India, with options for standard 50 kg polypropylene bags or custom bulk packaging upon request. Bulk ordering is available to accommodate large-scale testing or industrial requirements.Q: What process ensures the sand's consistent grading and purity?

A: The sand undergoes meticulous drying and screening to achieve strict particle size distribution, passing through ASTM standard sieves No. 20 and No. 30. Rigorous chemical analysis ensures high purity (SiO2 > 98%) and minimal trace elements, guaranteeing compliance with ASTM C778 and ISO 679 standards.Q: How does ASTM C778 20/30 Sand contribute to cement mortar performance?

A: By offering high purity and a controlled fineness, the sand enables mortar mixes to reliably achieve required compressive strength, in accordance with ASTM C109 specifications, making it indispensable for standardized cement performance evaluations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free