Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PMASTM D1556 /D1156M DENSITY SAND Fineness

Product Details:

- Application Used for sand cone method (field density determination of soil/aggregate)

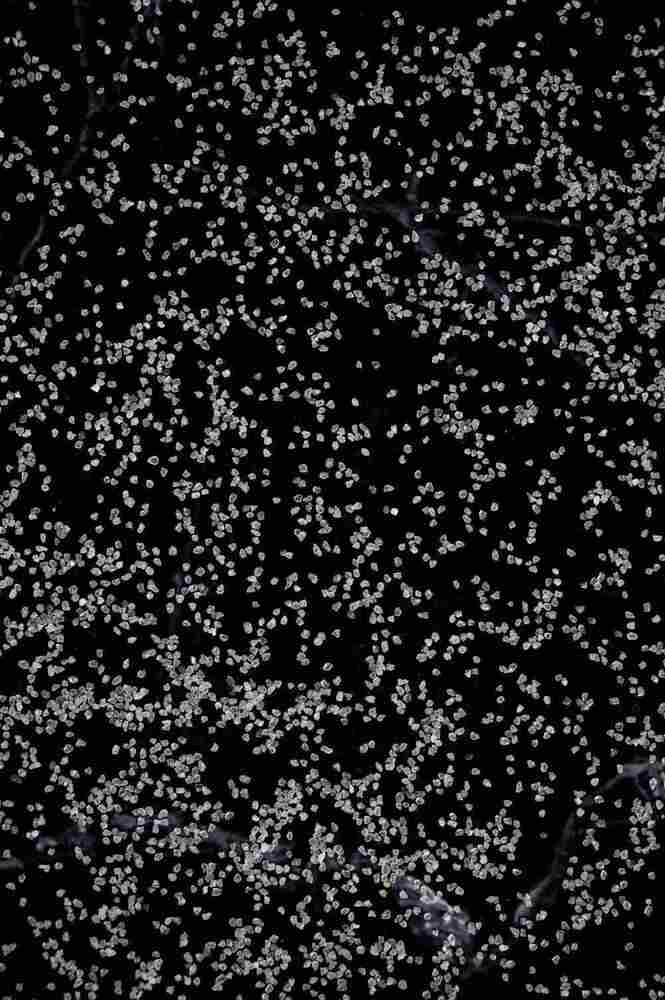

- Fineness Passing ASTM No. 20 Sieve, retained on ASTM No. 30 Sieve

- Color Light Tan/Beige

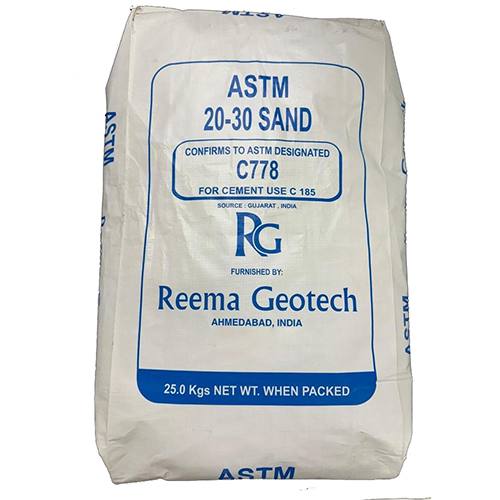

- Weight 50 lbs (22.7 kg) per bag (common packaging)

- Sand Type Calibration Sand (Standard Sand)

- Sand Fineness ASTM D1556 / D1156M-compliant Sand

- Natural Sand Type Standard Graded Silica Sand

- Click to View more

ASTM D1556 /D1156M DENSITY SAND Fineness Price And Quantity

- 3 Ton

ASTM D1556 /D1156M DENSITY SAND Fineness Product Specifications

- Standard Reference Sand for Density Determination

- ASTM D1556 / D1156M-compliant Sand

- Used for sand cone method (field density determination of soil/aggregate)

- Calibration Sand (Standard Sand)

- Passing ASTM No. 20 Sieve, retained on ASTM No. 30 Sieve

- Standard Graded Silica Sand

- 50 lbs (22.7 kg) per bag (common packaging)

- Light Tan/Beige

ASTM D1556 /D1156M DENSITY SAND Fineness Trade Information

- Per Day

- 7 Days

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

density sand is a key component. It is a standardized, dry, free-flowing sand used to determine the volume of a hole excavated in the ground, which is essential for calculating the in-place density of soil.

ASTM D1556/D1556M refers to the Standard Test Method for Density and Unit Weight of Soil in Place by the Sand-Cone Method. Therefore, "ASTM D1556/D1556M density sand" is a specialized product designed for use with this particular test method.

Here's a product description for ASTM D1556/D1556M density sand:

ASTM D1556/D1556M Density Sand

This high-quality, specially graded density sand is precisely manufactured to meet the rigorous requirements of ASTM D1556/D1556M (and often AASHTO T 191) for determining the in-place density and unit weight of soils using the sand cone method.

Key Features and Benefits:

* Precise and Uniform Grading: The sand is carefully sieved to a specific and consistent particle size distribution. This uniformity is crucial for ensuring reliable and repeatable density measurements, as it allows for consistent flow and filling of the test hole. Typically, few particles will pass the No. 200 (75m) sieve or be retained on the No. 10 (2.00mm) sieve, and the uniformity coefficient (Cu) is often less than 2.0.

* High Purity and Low Contaminants: Composed primarily of naturally rounded silica quartz, this sand is clean, dry, uncemented, and free from dust, clay, and other impurities. This high purity prevents interference with test results and ensures accurate density calculations.

* Consistent Bulk Density: The sand exhibits excellent bulk density consistency, with variations typically less than 1% between determinations. This stability is critical for the accuracy of the sand cone test, where the known bulk density of the sand is used to calculate the volume of the excavated soil.

* Free-Flowing Characteristics: The sand's uniform grain size and cleanliness ensure it flows freely and smoothly from the sand cone apparatus, allowing for accurate and complete filling of the test hole without voids or bridging.

* Durable and Reusable (with caveats): While designed for accurate testing, the sand is durable. However, it is essential to re-check its gradation and re-determine its bulk density if it becomes contaminated or after significant changes in atmospheric humidity. Reclaiming sand after testing is generally not recommended unless properly cleaned and re-calibrated.

* Complies with Industry Standards: Guaranteed to meet or exceed the specifications outlined in ASTM D1556/D1556M, ensuring compliance for civil engineering, geotechnical, and construction projects.

Typical Applications:

* Field Density Testing of Soils: Used with a sand cone apparatus to determine the in-place density and unit weight of compacted earth embankments, road fills, and structural backfills.

* Quality Control/Assurance: Essential for verifying the compaction of soils during construction to ensure compliance with project specifications.

* Geotechnical Investigations: Can be used for determining the in-place density of natural soil deposits, aggregates, and soil mixtures, provided the soil characteristics are suitable for the sand cone method.

Note: This sand is specifically intended for use with soils that are relatively cohesive, can maintain stable sides

PARAMETERS

[No.10] sieve size, less than 3% by weight passing the [No. 60] sievesize, determined in accordance with Test Method C136.Uniformly graded sand isneeded to prevent segregation during handling, storage and use. Sand free offines and fine sand particle is required to prevent significant bulk densitychanges with normal daily changes in atmospheric humidity.

SIEVE SIZE ( Mesh)

| % PASSING | |

| #10 | 100% |

| #60 | <3% |

The sieves designation are identified using thestandard system in accordance with specification E11

Test method conforming to ASTM C136.

Uniform Grading for Consistent Results

This calibration sand is uniformly graded to meet the specific requirements of ASTM D1556 / D1156M, ensuring reliable calibration of sand cone apparatus for field density tests. Uniform grading and minimal fines allow for consistent and repeatable measurements, critical for accurate soil assessment and quality control in construction projects.

Purity and Moisture Control for Accurate Calibration

The sand is meticulously washed to remove silt, clay, and organic matter, ensuring high purity for testing applications. With moisture content always maintained below 0.5% through oven drying, the risk of inaccurate density readings is minimized. This level of purity supports precise calibration and field density determination of soils and aggregates.

Robust Packaging for Use in the Field

Every batch of calibration sand is sealed in moisture-proof bags, each weighing 50 lbs (22.7 kg). This packaging preserves its optimal testing condition by preventing contamination and moisture uptake, making it convenient for transport, storage, and use on-site during geotechnical investigations and construction activities.

FAQ's of ASTM D1556 /D1156M DENSITY SAND Fineness:

Q: How is ASTM D1556 / D1156M density sand used in field density testing?

A: This sand is primarily utilized to calibrate sand cone apparatus, a device for determining the in-situ density of soils and aggregates. During the sand cone test, the standard graded sand fills the excavation in the test area, providing a reliable medium for measuring volume and weight, which enables accurate calculation of field density.Q: What distinguishes ASTM D1556 / D1156M sand from regular sand?

A: ASTM D1556 / D1156M sand is thoroughly washed, uniformly graded, and free from organics, silt, and clay. It passes through an ASTM No. 20 sieve but is retained on a No. 30 sieve, ensuring a specific particle size range crucial for calibration and density tests. Ordinary sand does not offer such stringent control over grading or purity.Q: When should calibration sand be replaced or repurchased?

A: Calibration sand should be replaced if it becomes contaminated, its moisture content rises above 0.5%, or its grading is affected by handling. Regular checks are recommended before every significant field testing campaign to maintain accuracy in density determination.Q: Where can ASTM D1556 / D1156M compliant sand typically be sourced?

A: You can procure this standard sand from manufacturers or suppliers specializing in geotechnical testing materials in India. It is generally available in 50 lbs sealed, moisture-proof bags for convenient handling and shipping.Q: What are the benefits of using this sand in sand cone field density tests?

A: Using ASTM D1556 / D1156M compliant sand ensures high accuracy, repeatability, and reliability in density assessments. Its uniform grading and low moisture content minimize variability and errors, enabling meaningful comparisons and effective quality control of construction materials.Q: Is there a specific process for preparing the sand before testing?

A: Before testing, verify the sand's moisture content is below 0.5% and that it is evenly graded without fines or contaminants. The sand should be loaded into the sand cone apparatus as per standard protocols to ensure consistent calibration and accurate volume measurements.Q: Can the sand be used for applications other than the sand cone method?

A: This sand is specifically designed for the sand cone method in field density determination. While its purity and grading may suit other geotechnical tests, it is not generally recommended for uses outside standardized calibration protocols.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS